Helical piers, also known as anchors, piles or screwpiles, are deep foundation solutions used to secure new or repair existing foundations. Due to their design and ease to install, they are most commonly used whenever soil conditions prevent standard foundation solutions. Instead of requiring large excavation work, they thread into the ground. This minimizes installation time, requires little soil disturbance, and most importantly transfers the weight of the structure to load bearing soil.

Helical Piers and Piles are needed for numerous new and existing residential, commercial, and industrial applications and may be used when the job specifies caissons, driven piles, or mini piles. Once foundations are exposed to moisture over a long period of time or construction is cited on unstable soil, structural and foundation damage becomes visible. This is when helicals are also used to correct compromised foundations. Helical Applications include, but are not limited to:

Homeowners choose them to prevent sagging foundations. If you are experiencing cracked foundations or drywall it may be signs that your foundation needs a permanent stability solution.

Contractors use our piering systems whenever the soil sample indicates a deep foundation solution. This is required when they want to avoid excavation expenses, such as tilt-up construction.

Plant managers love our anchors because of speed in which they are installed. With our system there is minimum impact to daily operations.

PierTech™ manufactures two patented types of piers. Round shaft, best used in compression situations, and square shaft best used in tension situations.

Made from the highest quality steel

Higher torque capacity than the competition

Superior lateral strength and stability

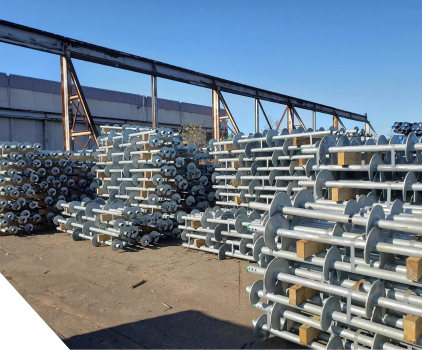

Galvanized or bare steel options

Square or round shafts

In applications where compression is the primary consideration, we recommend using round shaft piers. In Compression our round shaft has several advantages over the typical square shaft.

Get a QuoteIn applications where tension is the primary consideration, we recommend the Square Shaft Piers. They have several advantages over the typical square shaft anchors.

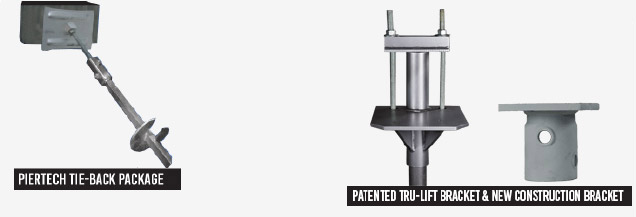

Our Patented Cross lock™ Connection was awarded ESR-3969 from ICC-ES for our 2.875″ diameter helical pile system. The connection instantly aligns and locks in place, eliminating the issue of lining up bolt holes or wasting time threading a bolt through a deformed hole. The Cross-Lock allows installers to simply connect and quickly continue the installation process.

The helical screw pile is screwed into the soil until a desirable load capacity has been achieved. It is then spaced at pre-calculated intervals to spread the load of the structure. In foundation repair applications, brackets are then attached to the foundation wall bases and weight is transferred to the pile.

Get a Quote

| Diameter | Single Helix | Double Helix | Triple Helix | Quad Helix | Extensions | Brackets |

|---|---|---|---|---|---|---|

| 1 1/2" | Spec Sheet | Spec Sheet | Spec Sheet | N/A | Spec Sheet | Spec Sheet |

| 2 7/8" | Spec Sheet | Spec Sheet | Spec Sheet | Spec Sheet | Spec Sheet | Spec Sheet |

| 3 1/2" | Spec Sheet | Spec Sheet | Spec Sheet | N/A | Spec Sheet | Spec Sheet |

| 4 1/2" | Spec Sheet | Spec Sheet | Spec Sheet | N/A | N/A | Spec Sheet |

| 5 1/2" | Spec Sheet | Spec Sheet | Spec Sheet | N/A | Spec Sheet | Spec Sheet |

Learn how to self- install or add it to your available services by becoming a certified installer.

Get a Quote