PierTech’s Highest-Capacity Hybrid Pile System

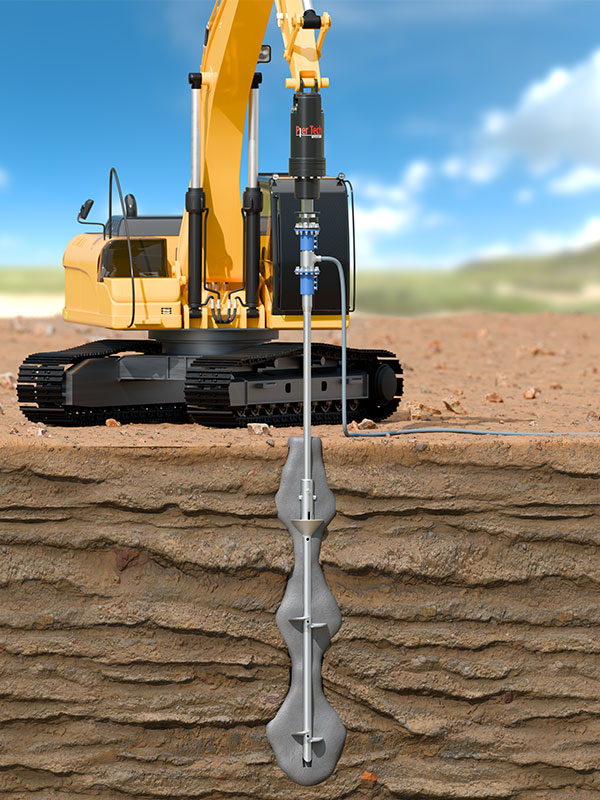

The Heli Max® Grouted Pile represents the next evolution in deep foundation technology — a hybrid, pressure-grouted, displacement helical pile that combines the best features of helical piles, micropiles, drilled displacement piles, and driven piles. This patented system delivers exceptional axial and lateral capacity while maintaining the speed, simplicity, and low-impact installation that define PierTech® foundations.

The Heli Max® system was engineered to solve one of the toughest challenges in foundation construction: achieving high capacity in limited-access or sensitive environments without the cost, mess, or vibration of traditional deep foundations.

By incorporating a displacement cone, dual-grouting module, and pressure-sealed grout column, the Heli Max® creates a confined, reinforced soil–grout interface that enhances both compression and tension performance.

Fast & Safe Installation

No Spoils

All Weather, All Soils

High Capacity

Zero Vibration & Low Noise

Install with Small Equipment

Requires only a standard excavator -no cranes or high-mast equipment needed.

Minimal Site Prep and access requirements

No spoils, no concrete trucks grout can be mixed and batched on-site

High compressive, tensile and lateral performance in a compact footprint

Low noise, low vibration installation ideal for sensitive areas.

No overhead hazards - safer crews and surrounding infrastructure

Pile sections are easy to transport, handle, and extend to required depth

Grouting process seals potential seepage paths, improving environmental protection

The Heli Max® Grouting Module enables pressure grouting to be performaed either:

Simultaneously along the pile shaft and lead section.

Post-grouted exclusively at the lead section for added end-bearing strength

Grout Discharge Ports positioned directly above the displacement cone

Lead-Section Ports along the entire length to ensure complete post-grout coverage

One-way Check Valve to maintain grout pressure until fully cured

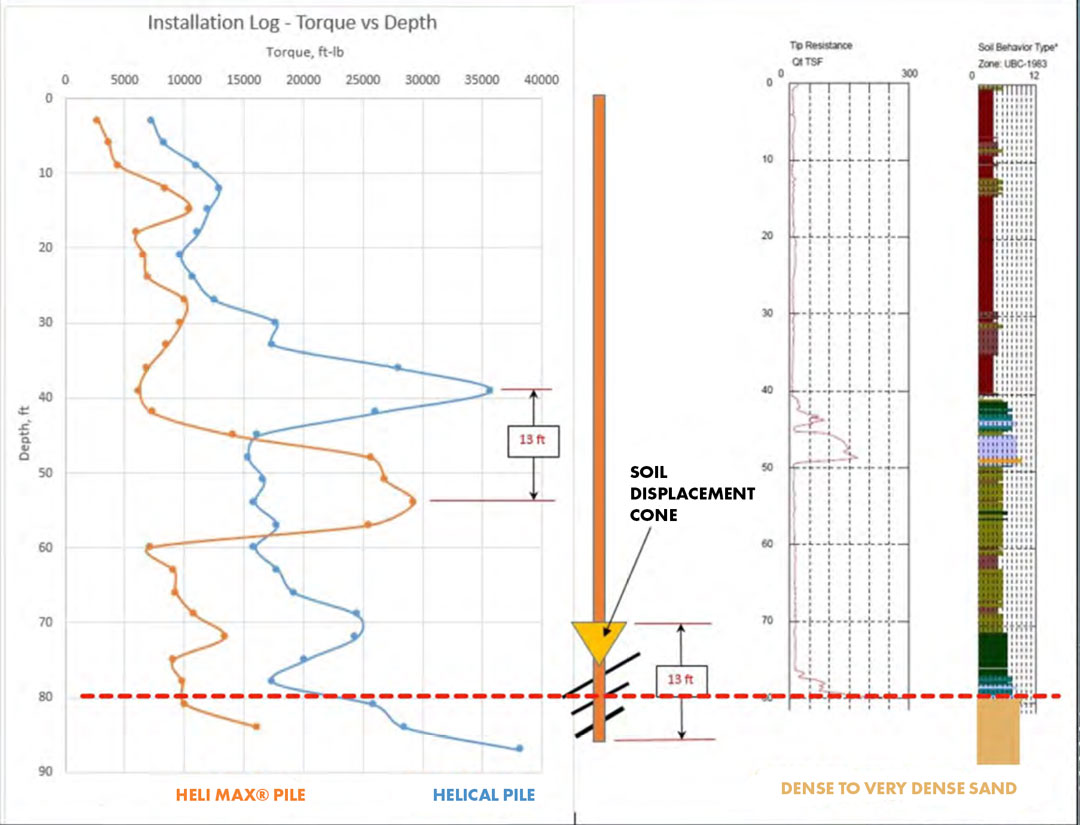

Displacement Cone that densifies soil and acts as a natural packer during grouting

The design allows controlled pressure grouting at precise intervals -ensuring a continuous, defect-free grout column that maximizes pile integrity.

As the Heli Max® is advanced, pressure pre-grouting is applied at regular intervals to counteract overburden and pore-water pressure. This creates a uniform, confined grout column free from voids or necking that could compromise load transfer.

Once the pile reaches final depth, post-grouting of the lead section is conducted under suffcient pressure to further increase end-bearing resistance and bond strength with the surrounding soil.

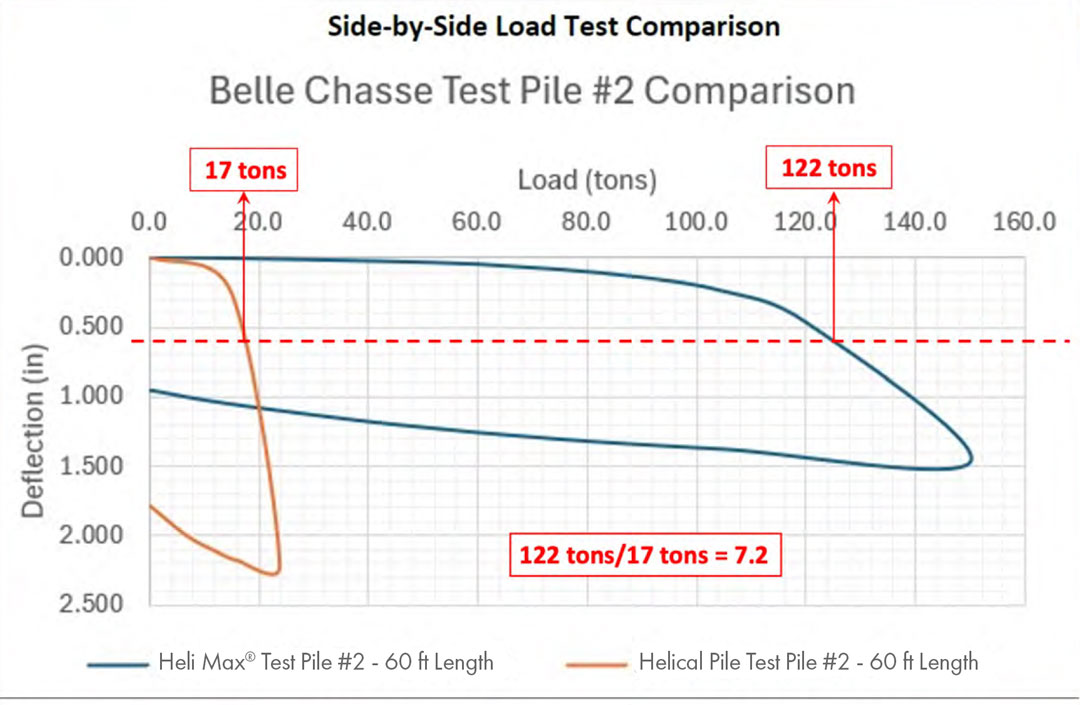

Load test comparing Heli Max® performance vs. a standard helical pier. In this test, the Heli Max® yielded over seven times the capacity of a standard pier.

Required installation torque of Heli Max® vs. a standard helical pier. In this text, Heli Max® requires significantly less installation torque than a standard helical pier.

The Heli Max® Grouted Pile is more than a pile - it's a new foundation category. By merging the efficiency of helical installation with the strength of pressure-grouted displacement systems, PierTech® continoues to deliver innovation you can install from blueprint to bedrock.

Get a Quote